Filtres à Air Automatiques à Rouleaux : Une Solution de Filtration de Précision pour l’Industrie, la Santé et les Centres de Données

Introduction

Une gamme complète d’analyseurs de haute précision est indispensable pour les secteurs qui exigent des mesures fiables et en temps réel. Utilisés dans les tests de composition chimique, la surveillance environnementale et le contrôle qualité, ces analyseurs assurent la performance des processus critiques.

De la même manière, les Filtres à Air Automatiques à Rouleaux incarnent ce principe de précision et de fiabilité dans le domaine de la gestion de l’air. Conçus pour les environnements industriels, commerciaux et hospitaliers, ils garantissent un flux d’air propre, stable et efficace, même dans des conditions de poussières intenses ou d’utilisation continue.

Dans des secteurs tels que les usines pharmaceutiques, les hôpitaux, les laboratoires, les centres de données et les camps pétroliers et gaziers, la qualité de l’air est un facteur stratégique pour la sécurité, la conformité réglementaire et la productivité.

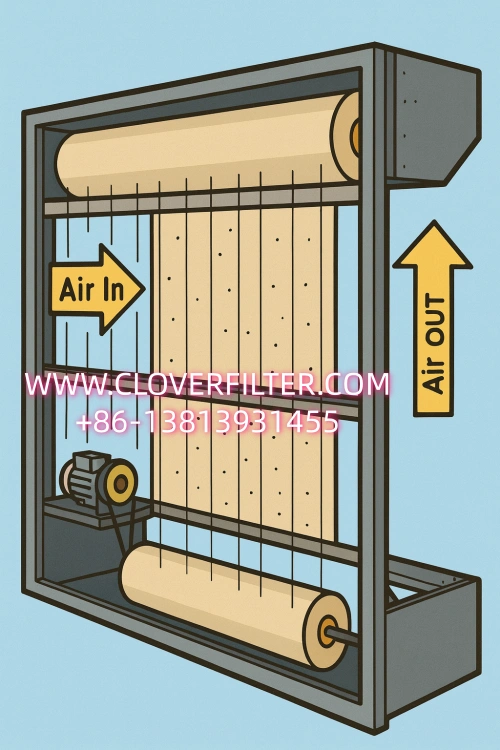

La Technologie des Filtres Automatiques à Rouleaux

Contrairement aux filtres classiques nécessitant des remplacements fréquents, le système automatique avance le média filtrant lorsque la perte de charge atteint un seuil défini.

Caractéristiques principales

-

Avancement automatique du média : remplacement contrôlé par PLC, assurant un fonctionnement continu.

-

Cadres personnalisables : acier galvanisé, acier revêtu, alliage d’aluminium ou acier inoxydable.

-

Média filtrant : fibres synthétiques ou coton non tissé, efficacité G3/G4 selon EN779.

-

Efficacité énergétique : conception optimisée réduisant la consommation des ventilateurs.

-

Compatibilité mondiale : tension 220V/380V/440V, monophasé ou triphasé.

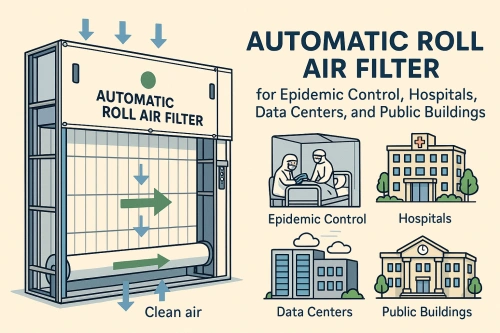

Domaines d’Application

1. Santé et Hôpitaux

Les filtres automatiques sont utilisés dans :

-

Les blocs opératoires et salles d’isolement.

-

Les services d’urgence et unités mobiles médicales.

-

Les systèmes de ventilation centralisée dans les hôpitaux.

Ils contribuent à la prévention des infections et à la sécurité des patients.

2. Usines Pharmaceutiques

Les environnements de production pharmaceutique doivent respecter les normes ISO 14644 et GMP. Les filtres automatiques garantissent :

-

La protection des salles blanches.

-

L’absence de contamination croisée.

-

La conformité réglementaire internationale.

3. Centres de Données

Les centres de données dépendent d’une circulation d’air stable pour protéger serveurs et équipements sensibles. Les filtres automatiques :

-

Prolongent la durée de vie des infrastructures IT.

-

Maintiennent une performance constante de refroidissement.

-

Répondent aux objectifs d’efficacité énergétique et ESG.

4. Camps Pétroliers et Gaziers

En zones désertiques ou offshore, la poussière est un défi majeur. Les filtres automatiques offrent :

-

Une protection de l’air dans les logements et postes de contrôle.

-

Une réduction de la maintenance manuelle.

-

Une sécurité renforcée pour les travailleurs.

5. Infrastructures Publiques

Dans les aéroports, gares et complexes sportifs, les filtres automatiques réduisent les coûts de maintenance et assurent une qualité d’air constante malgré des flux variables de passagers.

Avantages Comparatifs

-

Continuité : pas d’arrêt pour remplacement manuel.

-

Durée de vie allongée du média filtrant.

-

Coût global réduit sur le cycle de vie complet.

-

Conformité internationale avec EN779 et normes de ventilation hospitalière.

Perspectives Régionales

-

Amérique du Nord & Europe : priorité à l’efficacité énergétique et aux certifications environnementales (LEED, BREEAM).

-

Moyen-Orient & Afrique : besoin de résistance à la chaleur, à la poussière et aux environnements hostiles (hôpitaux, camps pétroliers, aéroports).

-

Asie-Pacifique & Amérique Latine : forte croissance des infrastructures médicales et industrielles, solutions adaptées aux budgets locaux.

Intégration avec les Analyseurs de Haute Précision

Tout comme les analyseurs de haute précision fournissent des résultats fiables pour la recherche et l’industrie, les filtres automatiques à rouleaux garantissent un environnement sans particules nuisibles. Ensemble, ils offrent :

-

Une précision accrue des tests en laboratoire.

-

Une meilleure qualité de production pharmaceutique et électronique.

-

Une sécurité renforcée dans les espaces de travail.

Conclusion

Qu’il s’agisse de centres de données, d’usines pharmaceutiques, de camps pétroliers ou d’hôpitaux, la maîtrise de l’air est un élément incontournable.

-

Les analyseurs de précision garantissent la qualité des mesures.

-

Les filtres automatiques à rouleaux garantissent la pureté de l’air.

Ensemble, ils renforcent la sécurité, la conformité et la performance des infrastructures modernes.

2025-09-30/10:13:33