Automatic Roll Filters: Advanced Air Filtration Technology for Hospitals, Airports, Data Centers, and Industrial Facilities

Introduction

Modern HVAC (Heating, Ventilation, and Air Conditioning) systems require reliable and efficient air filtration solutions. In critical environments such as hospitals, data centers, airports, cleanrooms, pharmaceutical plants, and large commercial buildings, maintaining clean and controlled air quality is essential for safety, compliance, and operational efficiency.

Automatic roll filters, also known as automatic roll air filters, have become one of the most practical solutions for high-volume air purification. They combine compact design, long operating autonomy, and minimal manual intervention, making them ideal for facilities that demand continuous and dependable filtration performance.

This article explores the construction, operation, applications, and advantages of automatic roll filters, highlighting why they are widely adopted across industries worldwide.

Key Performance Advantages

The main advantage of automatic roll filters lies in their long autonomy of operation and space-saving design. Unlike traditional filters that require frequent manual replacement, automatic roll filters use motorized media advancement to refresh the filter surface whenever the pressure drop reaches a certain level.

-

Compact size: Media rolls require only 10C20% of the total filter surface area, depending on filter size.

-

Extended operation: Reduced diameter rolls still provide maximum unwinding length, ensuring long service life even in harsh conditions such as dusty industrial environments.

-

Reduced downtime: Automatic advancement prevents system shutdowns for filter changes, which is critical in airports, hospitals, and cleanrooms.

These features significantly lower maintenance costs and improve system reliability.

Construction and Materials

Automatic roll filters are manufactured from pressed and bent galvanized steel sheets for durability. All parts are assembled with bolts and rivets, ensuring robust mechanical stability.

Main Components:

-

Filter Housing C Galvanized steel frame designed for duct or plenum installation.

-

Filter Media C Glass fiber or synthetic fiber rolls, often treated with adhesive oil to enhance dust retention.

-

Drive Motor System C Located at the base, it advances the filter media automatically.

-

Clean Roll Section C Upper compartment where unused media is stored under a protective cover.

-

Dirty Roll Section C Lower spool where used media is collected for easy disposal.

This construction ensures easy assembly, safe operation, and long-lasting performance even in demanding environments such as industrial factories or airport ventilation systems.

Standard and Custom Dimensions

Automatic roll filters are available in twelve standard widths (540 mm to 2130 mm) and variable heights from 1000 mm to 5000 mm. Heights increase in 100 mm increments, allowing customization to different duct sizes.

Custom-built dimensions are available on request, making these filters adaptable to unique projects such as large hospitals, pharmaceutical cleanrooms, or specialized data center HVAC systems.

Installation Guidelines

Installation of automatic roll filters is straightforward:

-

Delivered fully assembled for quick integration into duct or plenum systems.

-

For transport constraints, they can be supplied in pre-assembled components.

-

A minimum clearance of 800 mm is recommended for servicing operations.

-

Electrical connections link the control box to the drive motor and power supply.

Installation Options:

-

Direct airflow mode (FRA): Filter media roll positioned upstream.

-

Reverse airflow mode (FRI): Dirty roll downstream, fully covered.

-

Horizontal installation: Supported with chain tightener and twin rack system for flexibility in confined spaces.

These options make the filter versatile for data centers, airports, and pharmaceutical plants, where ductwork layouts vary widely.

Special Versions

Certain industries require higher levels of air filtration efficiency or additional functionalities. For these needs, special models are available:

-

FRM C Fully cased design, ready for direct duct installation or integration with air handling units (AHUs).

-

FRT C Equipped with additional frames for bag filters or rigid pocket filters, creating a compact multi-stage filtration unit.

Such configurations are popular in pharmaceutical industries, semiconductor cleanrooms, and large hospitals, where both particulate and microbial filtration are critical.

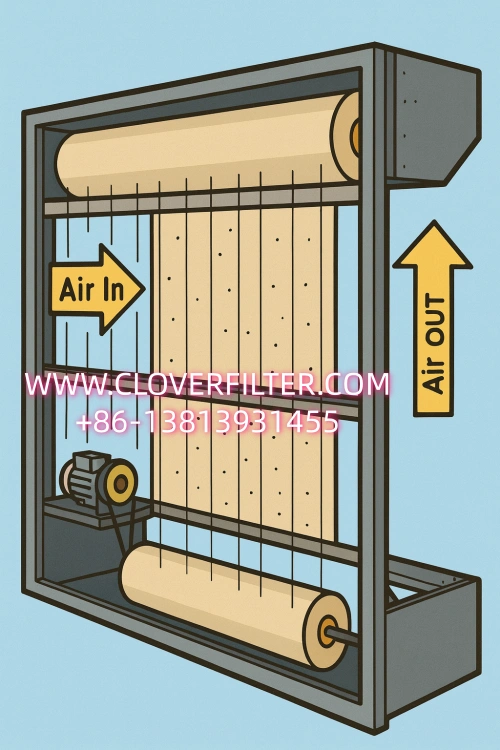

Principle of Operation

Automatic roll filters work on the viscous impingement principle. The filter media, impregnated with adhesive oil, captures airborne particles as air passes through.

-

When the filter reaches a preset pressure drop, a differential pressure switch activates the motor to unwind fresh media.

-

Side channels guide the media during unrolling, ensuring stability.

-

A metallic support grid on the outlet side prevents media deformation under airflow pressure.

This ensures constant air quality, reduced risk of bypass leakage, and energy-efficient operation, making the technology reliable in hospitals, airports, and data centers.

Control and Monitoring

Automatic roll filters include advanced control features for reliable operation:

These systems ensure that operators in industrial facilities or hospital HVAC departments can easily monitor and maintain the filter.

Applications Across Industries

Automatic roll filters are not limited to a single industry. Their versatility makes them useful in a wide range of environments:

1. Hospitals and Healthcare Facilities

-

Maintain sterile air quality in operating rooms and intensive care units.

-

Control airborne pathogens, reducing infection risks.

-

Support compliance with WHO and hospital air quality standards.

2. Airports and Transportation Hubs

-

Manage large volumes of air in passenger terminals.

-

Reduce dust and microbial contamination in HVAC systems.

-

Lower maintenance costs due to automatic filter media replacement.

3. Data Centers

-

Prevent dust accumulation on servers and electronic equipment.

-

Ensure uninterrupted cooling airflow for critical IT infrastructure.

-

Support compliance with ASHRAE and ISO standards for data center air quality.

4. Pharmaceutical and Cleanroom Industries

-

Guarantee ISO 14644 compliance in clean manufacturing areas.

-

Provide multi-stage filtration in combination with HEPA and ULPA filters.

-

Reduce manual intervention, minimizing contamination risks.

5. Industrial Manufacturing Plants

-

Handle high dust loads in production environments.

-

Support paint booths, electronics assembly lines, and food processing plants.

-

Lower energy consumption by maintaining stable pressure drop.

Global Relevance and Compliance

Automatic roll filters are used in UN projects, WHO healthcare programs, and World Bank-funded infrastructure developments, particularly in regions such as Africa, the Middle East, and Asia-Pacific.

They support compliance with international standards such as:

-

EN 779 / ISO 16890 C Air filter classification

-

ASHRAE standards C HVAC air quality requirements

-

Hospital and pharmaceutical GMP guidelines

Automatic roll filters are compact, durable, and efficient filtration systems for HVAC, industrial, and cleanroom applications. With their automatic media replacement, reduced downtime, and long service autonomy, they are widely used in hospitals, airports, pharmaceutical factories, data centers, and industrial plants.

They improve air quality, lower operating costs, and ensure compliance with international standards, making them a preferred solution for global projects requiring reliable air purification.