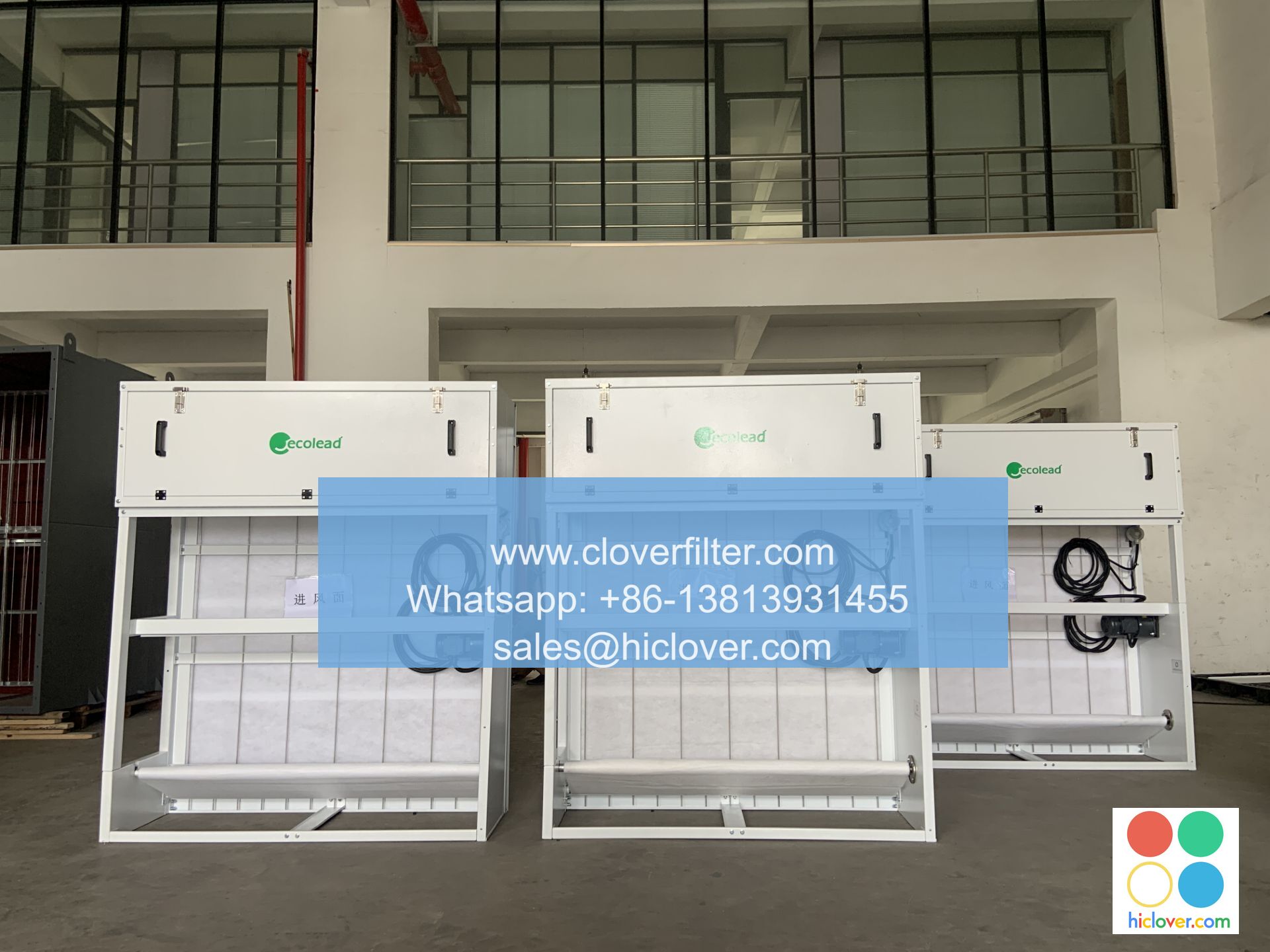

HICLOVER Automatic Roll Air Filter for Australia’s Mining and Energy Industries

Australia is a global leader in mineral resources, with extensive reserves of nickel, lithium, iron ore, and oil & gas. From battery plants in Western Australia to iron ore conveyor tunnels in the Pilbara region, air quality management is critical for safe and efficient operations. The HICLOVER Automatic Roll Air Filter is engineered to meet these demands with advanced self-advancing prefilter technology, ensuring continuous airflow and effective dust control in some of the world’s harshest industrial environments.

Automatic Roll Air Filter for Australian Nickel and Lithium Battery Plants

The rapid expansion of nickel and lithium battery production in Australia has created a need for specialized air filtration systems. Facilities in Western Australia and Queensland handle high volumes of fine particulates during ore processing, smelting, and cathode material preparation.

The automatic roll air filter for Australian nickel and lithium battery plants integrates PLC-controlled filter media advancement. By continuously replacing saturated filter sections with fresh material, it provides stable prefiltration before HEPA or ULPA systems. This minimizes downtime and reduces contamination risks, supporting the stringent quality requirements of battery-grade materials.

High Airflow Roll Filter Unit for Australian Iron Ore Conveyor Tunnels

Australia’s iron ore industry, especially in the Pilbara, operates massive conveyor tunnels transporting thousands of tonnes of ore daily. These environments are subject to extreme dust concentrations, abrasive particles, and high-volume ventilation needs.

A high airflow roll filter unit for Australian iron ore conveyor tunnels ensures coarse dust capture at the intake stage. The G3-grade synthetic fiber media removes larger particles, protecting downstream equipment and reducing the frequency of secondary filter replacement. The modular design of HICLOVER roll filters allows multiple units to be combined, handling airflow capacities exceeding 25,000 m3/h.

Continuous Filter Roll System for Australian Oil and Gas Ventilation

In Australia’s oil and gas sector, ventilation corridors in offshore platforms, LNG plants, and refinery workshops require durable and automated filtration systems. A continuous filter roll system for Australian oil and gas ventilation ensures stable intake air quality for blowers, compressors, and HVAC units operating in corrosive marine and industrial conditions.

HICLOVER filters are constructed from powder-coated carbon steel, stainless steel, or aluminum alloy profiles, ensuring long-term resistance to harsh climates. The 0.1 kW three-phase gear motor drives a reliable winding mechanism, while differential pressure sensors trigger automatic filter replacement. This provides consistent airflow while reducing operational risks in remote oil and gas installations.

Technical Advantages of HICLOVER Automatic Roll Air Filter

-

Automatic Control: PLC-based system with manual override and differential pressure monitoring.

-

Filter Media: G3 synthetic fiber, ideal for coarse dust prefiltration.

-

Motor Drive: Low-power (100W) three-phase gear motor ensures stable winding.

-

Modular Assembly: Multiple units can be joined for higher air volumes.

-

Durability: Designed for dust-heavy mining environments, including iron ore, coal, and nickel processing plants.

-

Energy Savings: Automatic filter replacement prevents high resistance, reducing blower energy consumption.

Why HICLOVER for the Australian Market

-

Adapted to Harsh Mining Conditions C Engineered for heavy dust loads and abrasive particles.

-

Supports Compliance C Meets occupational air quality standards required by Australian regulations.

-

Reduces Downtime C Automated filter media advancement minimizes manual replacement in remote mining camps.

-

Flexible Applications C Suitable for nickel and lithium battery plants, iron ore conveyor tunnels, oil and gas facilities, and bulk handling terminals.

Conclusion

Australia’s mining and energy sectors demand filtration solutions that are robust, automated, and efficient. The HICLOVER Automatic Roll Air Filter provides a tailored solution for nickel and lithium processing plants, iron ore conveyor ventilation, and oil and gas facilities, ensuring safe, compliant, and energy-efficient operations across the country’s most critical industries.

For technical specifications and tailored solutions for Australian projects, contact HICLOVER today.

Contact Information

Mobile (WhatsApp): +86-13813931455

Website: www.cloverfilter.com

Email: [email protected]

2025-09-02/14:11:46